The Ultimate Guide to Filling Tractor Tires for Better Performance and Efficiency

Filling tractor tires with the right liquid ballast can be crucial to enhancing your tractor’s traction and performance. In this guide, we’ll show you how to select the best ballast, no matter the tractor type, fill your tires effectively, and ensure your tractor operates at peak efficiency. Whether you’re considering calcium chloride, eco-friendly options, or just good old water, we provide the know-how for a straightforward tire filling process.

Key Takeaways

- Liquid ballast in tractor tires enhances traction and performance; options include calcium chloride, windshield washer fluid, beet juice, and water, each with its own pros and cons related to cost, weight, corrosiveness and suitability for different climates.

- Proper installation and maintenance of liquid ballasts are crucial, requiring specific equipment, safety precautions, and potentially the assistance of local tractor dealers; vigilance for and prompt repair of leaks are essential for continued performance.

- Alternative ballasting methods like ballast boxes, suitcase weights, and DIY counterweights provide different benefits and can be preferable based on individual needs and tasks; factors such as cost, climate, toxicity, freeze resistance and service life should influence the choice of liquid ballast.

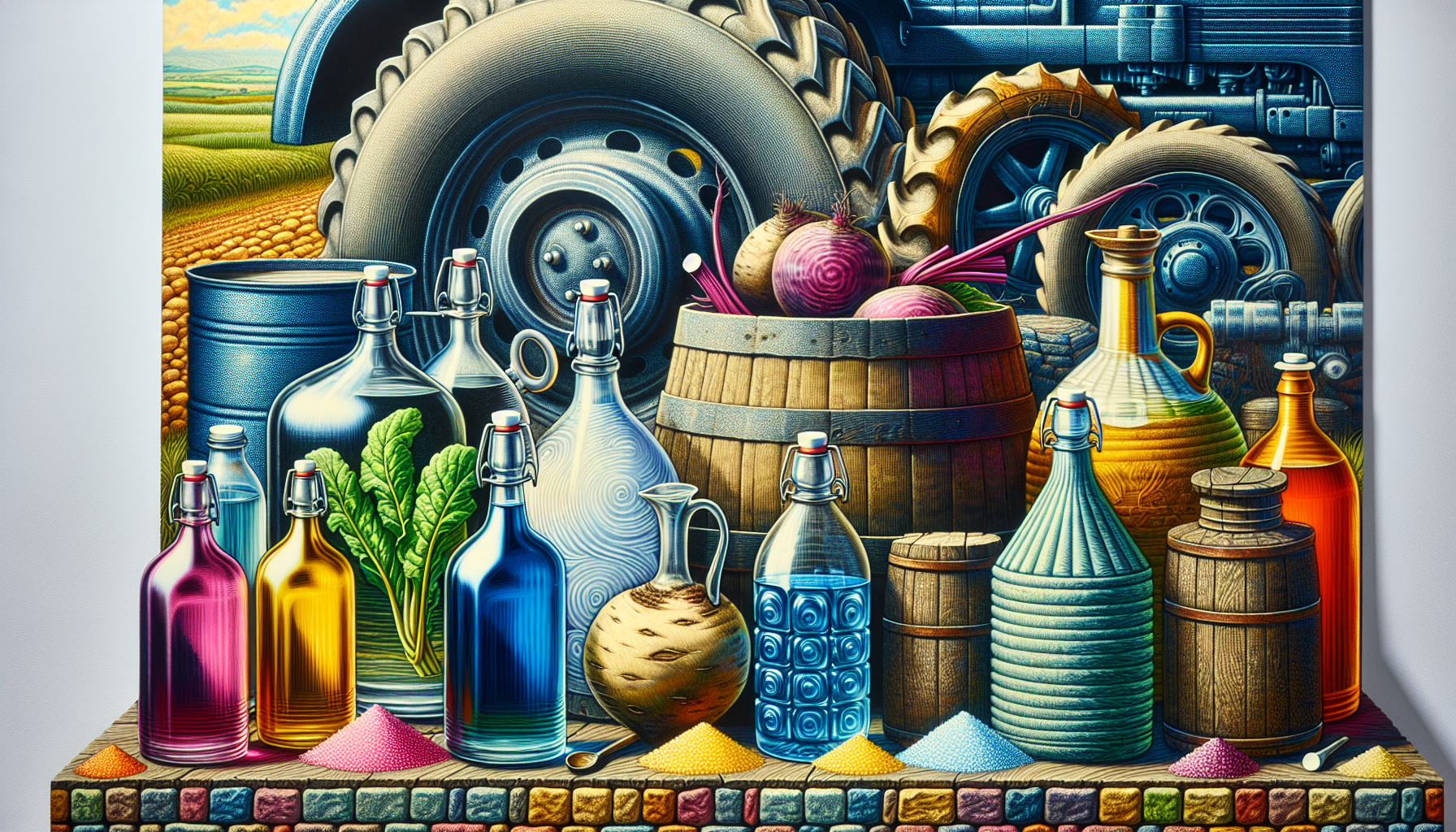

Understanding Liquid Ballast Options for Tractor Tires

Liquid ballast serves as an essential asset for many accomplished agriculturists, imparting the necessary heft to ensure your tractor maintains optimal traction during operation. The key is identifying which variant is most suited to your requirements by assessing the advantages and drawbacks of each variant.

Investigate the main liquid ballast options: calcium chloride, windshield washer fluid, beet juice, and simply using water—among these are some of the priciest liquid ballast choices available. Consider all possible liquid ballasts carefully in order to ascertain which aligns perfectly with your agricultural demands.

Calcium Chloride

Utilizing calcium chloride as a liquid ballast is favored for its density and affordability, surpassing alternative solutions by having a 40% greater weight compared to water. This significant heaviness enhances the tractor’s efficiency through increased ballast mass. There’s a downside: this substance can corrode your tractor tires and rims. Hence, specialists suggest fitting inner tubes as a protective measure.

Picture it like putting on rainwear during wet weather. You reap the rewards of rainfall without getting soaked!

Windshield Washer Fluid

Windshield washer fluid stands out as an economically and environmentally sound option if you’re looking for a cost-effective and eco-friendly ballast. This affordable alternative is readily available, it’s non-toxic, won’t eat away at tractor parts, thus safeguarding the environment while also protecting your machinery. Its weight profile is similar to that of plain water. Hence the additional heft it provides when utilized as ballast may be somewhat modest.

Consider it analogous to choosing a lightweight boxer – they might not pack the most powerful punch due to their lighter build but compensate with speed and nimbleness!

Beet Juice

For environmentally conscious individuals who want to protect their tractor parts, consider filling tractor tires using beet juice as a liquid ballast. It’s an eco-friendly alternative that is both non-toxic and non-corrosive, plus it has the advantage of being freeze-resistant, which makes it ideal for use in colder regions. Beet juice weighs approximately 11.0 pounds per gallon.

Adopting this green solution can be similar to purchasing an electric vehicle. While beet juice may indeed come with a higher price tag compared to other ballast options, the investment pays off over time due to its long-term advantages!

Plain Water

Lastly, the simplest and most cost-effective ballast alternative is none other than plain water. This time-honored solution has been deployed extensively to enhance grip and minimize skidding. Yet, its vulnerability to freezing renders it an impractical choice in frosty environments.

Introduce a bit of propylene glycol or similar antifreeze into the mix, though, and you obtain a dual benefit: a ballast that resists freezing temperatures while also warding off corrosion.

The Process of Liquid Ballast Installation

Once you’ve selected the appropriate liquid ballast for your needs, the installation procedure includes elevating the back tires of your tractor, extracting the valve core, and employing either a gravity-based filling technique or a transfer pump to introduce the ballast into the tires. While this task isn’t overly complicated like rocket science might be, it still demands careful consideration to detail and possession of suitable tools.

Equipment and Safety Precautions

For both do-it-yourselfers and professionals, safety should always be a top priority. Crucial tools include a tire valve stem tool, an air/water adapter kit, and a pump to move liquid. It’s important to elevate the tractor with a suitable jack while ensuring it is safely supported by jack stands to avoid any mishaps. When dealing with ballast fluids that could be corrosive or toxic, wearing protective gear is vital.

Think of this as preparing for an expedition. Possessing the correct equipment and employing it securely is fundamental.

Working with Local Tractor Dealers

In the realm of tractor tire business, numerous local tractor dealers can serve as valuable partners. Their expertise on various tractor models means they can assist you in selecting the appropriate type and quantity of ballast for peak functionality. These tractor dealers are equipped to instruct you on the proper upkeep of your tires once they’ve been filled with ballast.

Should you prefer a more do-it-yourself approach, these same dealers offer self-service alternatives by providing fill valves needed for tire inflation. Consider them akin to personal trainers who are ready to either coach or supply you with necessary equipment to manage independently.

How to Detect and Repair Liquid Ballast Leaks

Just as a ship’s captain must be watchful for any leaks, it is crucial to remain attentive to potential liquid ballast leaks within your tractor tires. Such leaks can impair the performance and stability of your tractor—a scenario you definitely want to avoid while engaged in an important job.

Identifying Leaks

To detect a leak, you can employ various techniques which include:

- Inspecting the valve stem

- Utilizing an electronic stud finder

- Observing for tangible indicators such as a moisture trail on the tire or listening to any liquid sounds within when swaying the tire

These strategies will aid in discerning whether your tire has developed a leak.

It’s comparable to engaging in detective work — meticulous scrutiny and probing are essential in pinpointing the source of the problem.

Causes and Repairs

Leaks in the liquid ballast, such as those from calcium chloride, which can corrode wheel rims, may be a result of damage to these components or due to an inadequate valve core. Fixing a leak in your tire’s liquid ballast is similar to repairing a bike tire puncture: it requires using sealing agents and replacing faulty valve cores. Once addressed properly with the correct repairs, your equipment will be set for operation once again.

Alternative Tractor Ballasting Methods

Though many favor liquid ballasts, they’re not the sole choice available. Other approaches to ballasting like tractor ballast boxes, suitcase weights, and homemade counterbalances may better align with your particular requirements. These options provide varied benefits and greater adaptability, enhancing your ability to fine-tune the performance of your tractor.

Ballast Boxes

Ballast boxes provide a simple and flexible solution for ballasting, with the added advantage of serving as tool storage depending on their design. Think of them as a combination of a weight set and toolbox all in one handy unit!

Suitcase Weights

Another option for ballasting is suitcase weights, which are notable for their versatility. These can be swiftly attached to or removed from the tractor wheels, allowing adaptability across a range of different jobs.

This process can be likened to modifying the leg weights in your exercise routine. You adjust them depending on the specific activity you’re undertaking.

DIY Counterweights

DIY aficionados will find that making their own counterweights offers both a sense of accomplishment and the benefit of cost savings. Using a 50-gallon plastic drum filled with concrete, you can easily construct a substantial counterbalance suitable for your tractor.

The process is similar to assembling personalized workout gear at home— it’s not only economical but also tailored to meet your precise requirements!

Factors to Consider When Choosing a Liquid Ballast

When selecting the appropriate ballast for your needs, it’s important to consider a multitude of factors that can influence your decision. These criteria include the cost of materials, compatibility with local climate conditions, availability of non-toxic variants, resistance to freezing temperatures as well as the expected service life of the ballast product.

Cost

The decision on which liquid ballast to use is heavily influenced by cost considerations. Although plain water serves as a cost-free choice, it doesn’t provide some of the benefits that come with pricier options. The scenario is comparable to choosing between a standard bicycle and an electric one—despite both fulfilling the same function, enhanced features are accompanied by higher costs.

Local Climate

The climate in your area plays a significant role as well. The choice of ballast fluids tends to vary globally, reflecting regional selections influenced by local weather conditions.

Think of it like picking out what to wear – just as you wouldn’t choose a heavy winter jacket during hot summer months, similarly certain ballasts are preferred depending on the climate.

Non-Toxic Options

Should you prioritize environmental stewardship, selecting non-toxic alternatives would naturally align with your values. These options safeguard both the ecosystem and your tractor parts. It’s akin to choosing organic produce instead of processed edibles – a commitment to nurturing both the earth and personal well-being!

Freeze Resistance

Especially when residing in a colder region, considering the freeze resistance is essential. Just as you choose suitable insulation to protect your home from chilly temperatures, ensuring that your ballast doesn’t solidify during winter is equally important for maintaining function and performance.

Service Life

Take into account the service life. Your selection of liquid ballast can greatly affect both the durability and upkeep requirements of your tire. Think of it akin to choosing a durable light bulb – you’re looking for an option that stands the test of time!

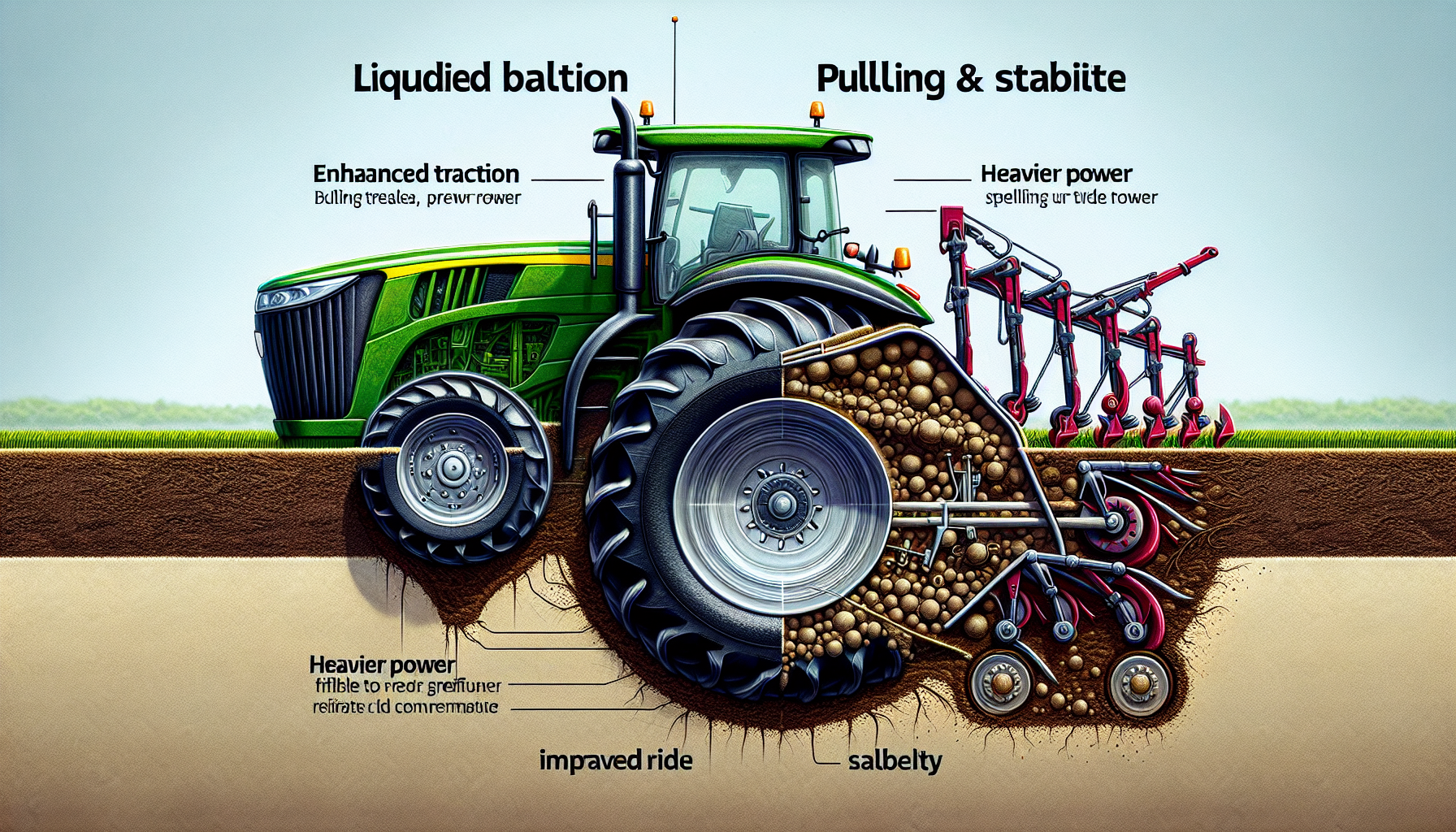

The Impact of Liquid Ballast on Tractor Performance

The genuine effect of utilizing liquid ballast in a tractor is that it enhances the machine’s traction, elevates its pulling capability, stabilizes it and improves the comfort of the ride. Nevertheless, one should be aware that this can lead to additional stress on the engine and potentially hinder agility.

Tractor Power and Pulling Power

Using liquid ballast increases the conversion of engine horsepower into additional tractor power, thereby boosting your tractor’s effectiveness and operational capability. It’s similar to upgrading the engine in your car – you will definitely observe a marked difference!

Stability

Improving stability and preventing accidents, particularly on slopes and uneven surfaces, is a benefit of liquid ballast. It acts as a counterbalance to reduce the risk of rollovers. Our service includes providing liquid ballast installation which not only bolsters your safety but also optimizes the performance of your vehicle.

Equating this to having a reliable pair of hiking boots is appropriate. They also provide essential traction and stability when navigating through tough terrains!

Ride Quality

It’s important to recognize that though numerous benefits exist, the increase in weight due to liquid ballast might result in a more jolting ride along with diminished rates of acceleration and deceleration. This additional weight impacts the tractor’s agility and its capacity for prompt response.

The experience is akin to contrasting driving experiences between a fully laden truck and an agile sports car—both come with their own set of pros, but they offer distinct sensations when driven.

Summary

Keeping your tractor tires properly ballasted is key to maximizing their performance and efficiency. Whether you choose liquid ballast or alternative methods, remember that each option has its pros and cons. Assess your needs, consider factors like cost, local climate, toxicity, freeze resistance, and service life, and choose wisely. After all, the success of your farming operation could hinge on something as simple as what’s in your tractor tires!

Frequently Asked Questions

What is best to fill tractor tires with?

To enhance traction, filling tractor tires with a calcium-water blend is optimal. This compound should be introduced through the valve stem when it’s positioned at its peak elevation. The technique details necessary data about the quantity, mass, and lowest temperature thresholds applicable to an array of tire dimensions and mixture ratios.

How do you fill water in a tractor tire?

When adding water to a tractor tire, first hoist the tractor with a jack and let out any necessary air. Ensure that the valve is at its highest point, then employ an exclusive device designed for injecting water into the tire via the valve stem. You can find these specialized tools at dealerships that sell farm machinery as well as select car parts retailers.

How much rim guard per gallon?

Utilize rim guard at a rate of 11 pounds for each gallon.

This heavy solution, derived from beet juice, is non-toxic to animals and will not cause corrosion.

What are the main types of liquid ballast for tractor tires?

Various types of liquid ballast, including calcium chloride, windshield washer fluid, beet juice, and plain water, are used in tractor tires. Each of these options offers unique benefits and factors to consider.

What are some alternative tractor ballasting methods?

Alternative methods for tractor ballasting, such as utilizing ballast boxes, suitcase weights, or creating your own DIY counterweights, can offer both flexibility and cost-efficiency to meet your specific ballasting requirements.